Job Description:

- Individual will assist our Account Managers and be an additional point of contact with future and current customers.

- Capable of supporting and expanding existing and new accounts.

- Help Account Managers develop machine processes and conceptual layouts.

- Assist Account Managers in day to day quoting and engineering needs.

- Apply knowledge of mechanical, electrical, and controls systems to develop and quote turn-key automation solutions.

- Develop concepts and apply quotes and costs to customers ideas.

- Work alongside our Mechanical Engineers to review projects and ensure compliance with customer drawings and specifications.

Experience:

- Assisting with customer account management

- Follow up on sales leads

- Basic knowledge in Mechanical, Electrical, Controls/Robotics

- Experience in Project management and/or account management is desired

Qualities:

- Team Player

- Good Communication

- Organized

- Creative, analytical, and driven

Position Requirements:

- Degree in Engineering or related field

- 3-5 years’ experience with industrial automation equipment

- Success in account prospects and continued maintenance of key accounts

- Familiarity in sales of automation solutions

- Interpersonal skills and customer service

- Have a strong foundation in engineering fundamentals

- Familiarity with CAD software is appreciated

- Ability to work independently and in a team atmosphere

Position Overview:

Perform panel build, machine wiring, and debug related to build special machinery for the commercial, industrial, and automation industries. Team members install, support, upgrade, repair, and modify equipment at customers facilities.

Job Description:

- Do work requiring a thorough knowledge of electrical theory and principles, statutory codes, properties of materials and principles of operation of electrical equipment

- Analyze circuits, wiring diagrams and drawings supplied by electrical engineers

- Implement electrical panel build and machine wiring per supplied engineering drawings

- Implement custom machine start up, trouble-shooting, and debug related to the build process

- Service existing equipment and/or perform warranty work related to electronic equipment by checking, testing, and replacing faulty components, circuits, and similar electronic devices

- Determine the need for, analyze, and make necessary running adjustments, repairs, or modifications to engineering drawings to satisfy the requirements of custom machinery build

- Testing, troubleshooting and problem-solving skills are critical

Minimum Qualifications:

- 3+ years of experience in the related industry

- Vocational school or junior technical college training in the related industry is a plus.

- Ability to climb, work beneath machines, and in close quarters performing noted tasks related to machinery build and repair work

- High degree of attention and care required to prevent industry to self and others

- Baseline robotic knowledge is a plus for the position

- Maintain a clean and safe work environment

- Willingness to travel on installs

- Must furnish the basic hand tools of the trade

- Willingness to work and alter work schedule as needed

- Ability to work independently and in a team atmosphere, with good communication and multi-tasking skills

Schedule: 4×10 Monday-Friday

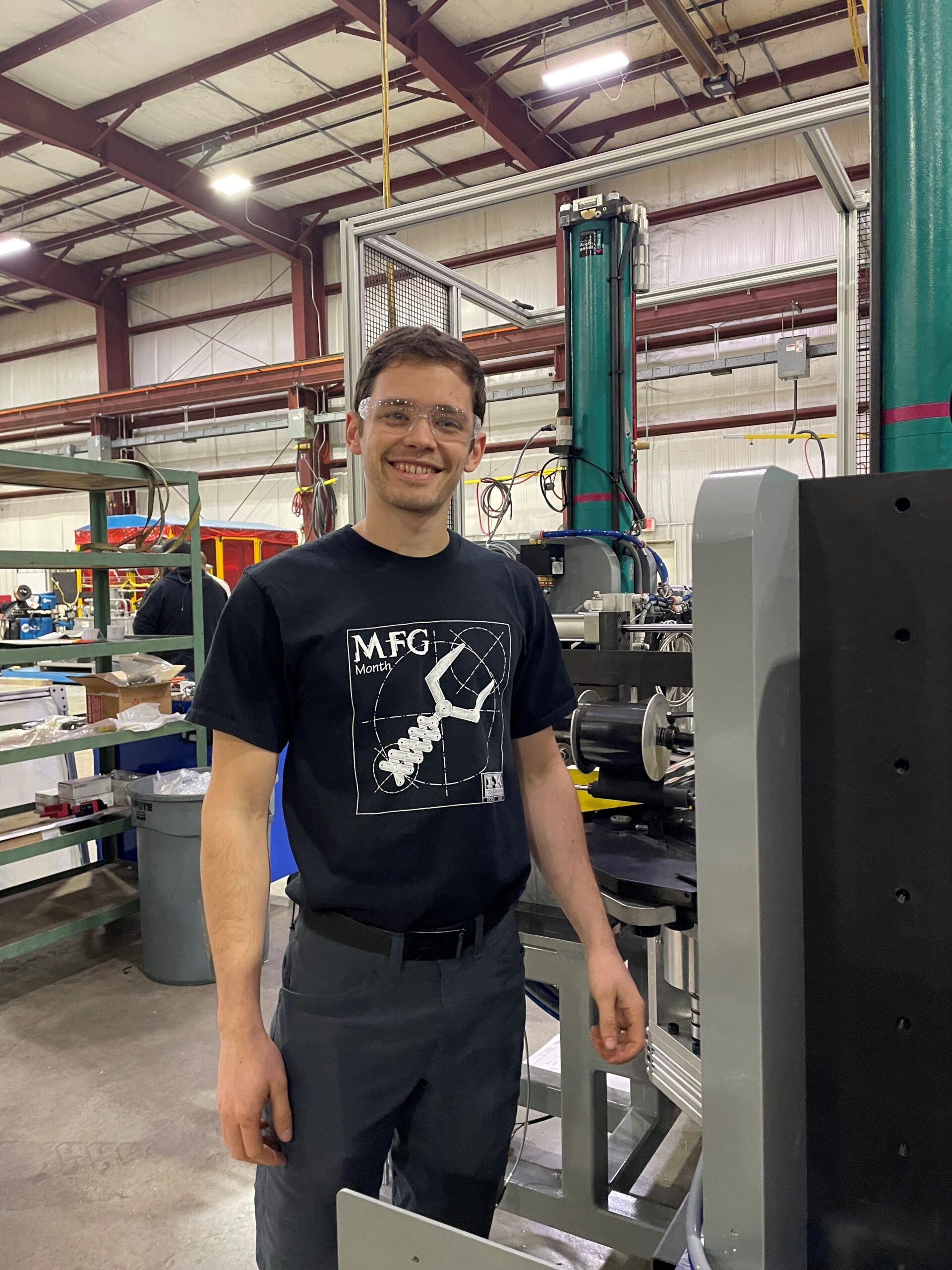

Job Description: Individual will utilize equipment or machines such as, lathes, and mills for shaping, drilling, milling, turning, and grinding. During the day-to-day machining task, machinist will read and use schematics, blueprints, software and manuals.

Experience:

- 5 axis Hurcos

- 4 axis HAAS

- 3 axis HAAS

- Lathes & Knee Mills

- 2D & 3D machining using CAD/CAM software

- Gauges, calipers, indicators, micrometers and scales

Position Requirements:

- 2-5 years of machining experience

- Operate vertical and horizontal metal cutting saws

- Reading take measures and other measuring equipment

- Selecting proper materials and other measuring equipment

- Capable of programming on CAD/CAM software

- Maintain a clean and safe work environment

- Review drawings, instructions, blueprints to ensure accurate production

- Capable of inspecting own parts to spec, prior to quality review

- Ability to work independently and in a team atmosphere

Skills:

- Problem Solving

- Time management

- Good work ethic

- Analytical skills

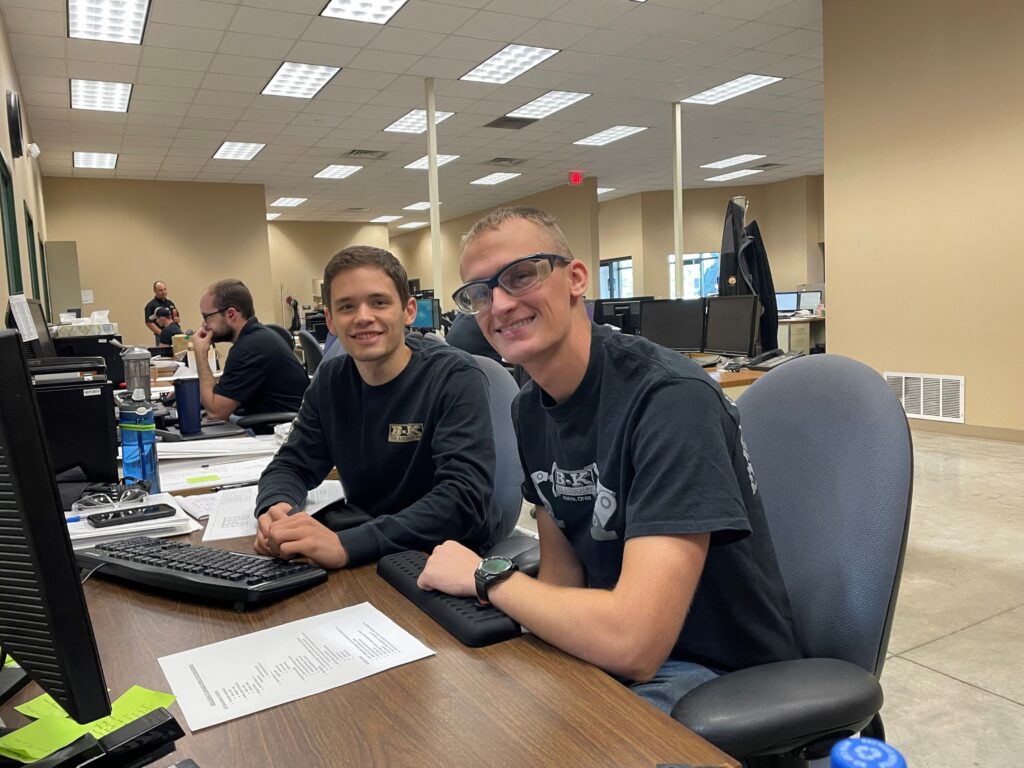

Job Description:

Individual will assemble mechanical, pneumatic, electro-mechanical, and hydraulic equipment for automated custom-built production tools and systems. Testing, troubleshooting and problem-solving skills are critical. Team members install, support, upgrade, repair, and modify equipment at a customer’s facility.

Experience:

- Strong mechanical aptitude and experience

- Power hand tools

- Machine building or similar

- Blueprint reading

- Robotic knowledge is appreciated (Fanuc, Motoman, Nachi, ABB)

- Team plater

- Good communication

- Organized

- 1-2 years of assembly or mechanical systems experience

- Lifting, bending, kneeling and standing

- Reading blueprints and schematics

- Selecting proper materials and tools according to blueprint

- Maintain a clean and safe work environment

- Construct small to large parts, components, and systems to create new products

- Review drawings, instructions, blueprints to ensure accurate production

- Ability to work independently and in a team atmosphere

- Some overtime and travel required

Full-Time Employee Benefits:

- Comprehensive Health Insurance

- 401-K Retirement with Employer Match

- Company Paid Life Insurance

- Company Paid Short- & Long- Term Disability

- Flexible Schedule

- Steel Toe Booth Reimbursement Program

- Profit Sharing / Performance Bonus

As a team, we are able to make customers ideas, come to life.